In industries where accuracy and material preservation are critical, Coring Drill Bits serve as indispensable tools. Unlike conventional drilling equipment that focuses solely on creating holes, coring bits are specifically engineered to extract intact cylindrical samples while cutting through rock, concrete, or other solid materials. This unique function makes them valuable in geological exploration, mining operations, oil and gas research, construction, and environmental studies. Their ability to combine efficient drilling with reliable core recovery has cemented their role in projects that demand both speed and scientific precision.

What Are Coring Drill Bits?

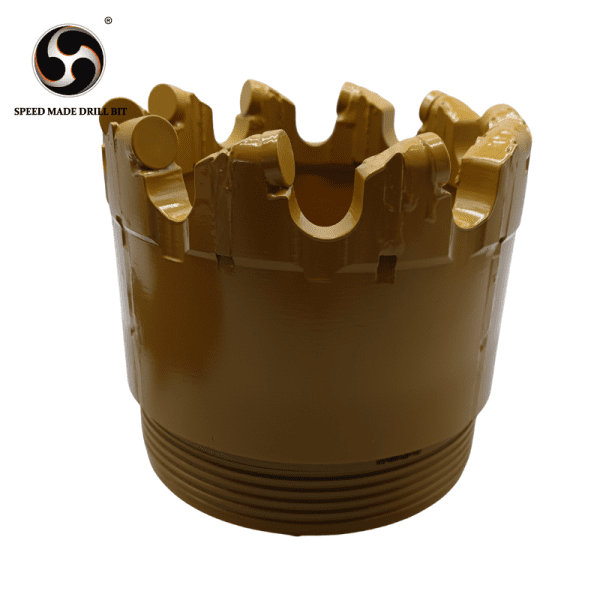

Coring drill bits are designed with a hollow structure that cuts only the outer circumference of the hole, leaving behind a cylindrical core inside. This structural difference is what separates them from regular drill bits, which pulverize the material entirely. By recovering samples, coring bits provide crucial insights into subsurface conditions, helping geologists, engineers, and project managers make informed decisions.

The materials used in coring bits vary according to their intended applications. Diamond coring bits are widely regarded as the most effective for hard and abrasive surfaces, while tungsten carbide bits are preferred for softer formations. In more demanding industries such as oil and gas, advanced variations like polycrystalline diamond compact (PDC) coring bits are employed to achieve both durability and high penetration rates.

Applications Across Industries

The versatility of coring drill bits is evident in their widespread use across multiple fields. In geology and mining, they are critical for exploration, enabling specialists to study the composition, structure, and mineral content of rock formations. These samples reveal valuable information about potential ore deposits or the stability of a site before excavation begins.

In construction, coring bits are used to create precise openings in reinforced concrete, masonry, or asphalt for installing utility lines, anchor bolts, or structural reinforcements. They are also essential in quality control and safety inspections, where engineers analyze concrete cores to assess strength and durability.

The oil and gas industry relies on core samples for reservoir evaluation, helping determine porosity, permeability, and hydrocarbon potential before large-scale drilling commences. Similarly, geothermal projects employ coring bits to explore subsurface conditions and locate optimal drilling sites. Environmental studies also depend on these tools for soil and rock sampling, providing accurate data for contamination analysis, groundwater monitoring, and land stability assessments.

Advantages of Coring Drill Bits

One of the most significant benefits of coring drill bits is their ability to preserve the structural integrity of extracted samples. This ensures that laboratory analyses yield accurate data on mineral composition, rock density, or fluid saturation levels. Such precision is vital for exploration projects, structural assessments, and scientific studies.

Another advantage is efficiency. Because coring drill bits cut only the perimeter of a hole, they require less energy than conventional full-face drilling tools. This reduces wear on equipment, extends bit lifespan, and minimizes operational costs. When paired with proper cooling methods such as water or drilling fluids, coring bits can maintain consistent performance even in abrasive conditions.

Their adaptability further enhances their value. Whether used in handheld equipment for small-scale construction tasks or in large rotary rigs for deep exploration, coring drill bits can be applied in diverse environments. This flexibility makes them a universal choice for professionals across multiple sectors.

Design Innovations in Coring Drill Bits

Advancements in technology have transformed the performance and durability of coring drill bits. Modern designs incorporate synthetic diamond segments, engineered for greater thermal resistance and cutting power. Optimized blade configurations and improved fluid channels ensure effective cooling and debris removal, which reduces the risk of clogging and enhances drilling speed.

Hybrid coring bits, combining diamond impregnation with advanced matrix composites, have also emerged as solutions for extremely challenging conditions. These innovations allow for steady penetration in hard formations, ensuring reliable core recovery without compromising efficiency. Additionally, smart drilling technologies are beginning to integrate sensors into drilling systems, providing real-time feedback on bit performance and enabling operators to adjust parameters for maximum productivity.

Comparing Coring Drill Bits with Standard Drill Bits

The distinction between coring drill bits and conventional drill bits lies in their purpose and efficiency. Standard drill bits are designed to break and remove material, creating holes without preserving any samples. While effective for general construction, they offer little value in industries where sample integrity is essential.

Coring bits, on the other hand, are designed for dual functionality: creating boreholes and retrieving intact cores. This dual advantage reduces waste, provides crucial data, and enhances overall project accuracy. Although coring bits may carry higher upfront costs, the long-term benefits of sample recovery and reduced wear often outweigh the initial investment.

Challenges and Considerations

Despite their many advantages, coring drill bits do present certain challenges. Hard, abrasive formations can accelerate cutter wear, particularly if improper cooling is used. Heat buildup is a common concern, as excessive temperatures may damage bit integrity and reduce sample quality. Selecting the appropriate bit for specific geological or structural conditions is essential to achieving optimal results.

Another consideration is cost. Diamond coring bits, while highly effective, are more expensive than carbide or steel alternatives. However, their durability and performance in hard formations often justify the expense by reducing downtime and improving recovery rates.

Future Outlook

The future of coring drill bits is closely tied to ongoing innovation in materials and drilling technology. With industries moving toward deeper, more complex drilling environments, demand for advanced coring solutions will only increase. Research into ultra-hard synthetic materials and nanostructured composites promises to extend bit life and enhance cutting power.

At the same time, the integration of artificial intelligence and automated drilling systems is likely to improve precision and efficiency in real-time. Sustainability is also becoming a focus, with manufacturers seeking ways to reduce energy consumption and environmental impact during coring operations. These trends highlight the continued importance of coring drill bits in shaping the future of exploration and construction.

Conclusion

Coring drill bits are more than just tools; they are precision instruments that bridge the gap between drilling efficiency and scientific accuracy. By delivering intact samples and ensuring clean boreholes, they serve vital roles in mining, geology, construction, oil and gas, geothermal energy, and environmental studies. Their advantages in durability, adaptability, and performance make them invaluable for modern projects that require reliable data and precise drilling. With ongoing innovations in design and materials, coring drill bits will remain central to industries that depend on accuracy, efficiency, and sustainable exploration.