Resin 3D prints have become a hallmark of modern additive manufacturing, known for their extraordinary precision and fine detail. As industries increasingly embrace rapid prototyping and custom production, resin-based models stand out for their smooth finishes and ability to capture intricate geometries. Whether in dentistry, jewelry, engineering, or creative hobbies, resin 3D printing has set a new standard for what digital fabrication can achieve. This article takes a closer look at how resin prints are made, the advantages they offer, their wide-ranging applications, and why they continue to grow in popularity.

Understanding Resin 3D Printing

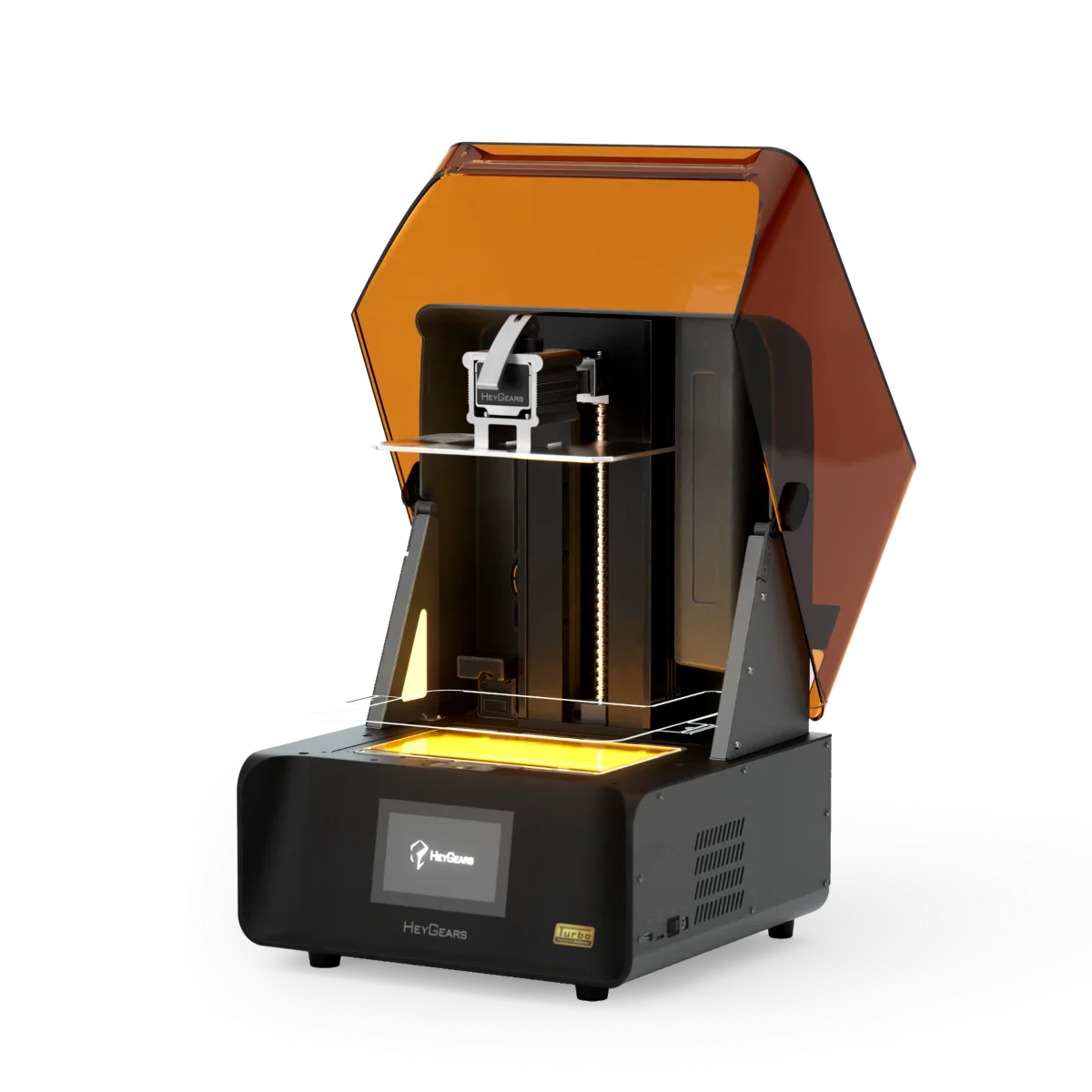

At the foundation of resin 3d prints is photopolymerization, a process where liquid resin hardens under specific light exposure. Unlike filament-based printing that melts and extrudes plastic, resin printing builds objects layer by layer using light sources such as lasers, digital projectors, or LCD screens. This results in surfaces that are exceptionally smooth with minimal layer visibility.

Common technologies behind resin printing include SLA (stereolithography), DLP (digital light processing), and MSLA (masked stereolithography). While they vary in mechanics, each is capable of producing high-resolution objects that appeal to both professionals and enthusiasts.

What Makes Resin 3D Prints Unique

The defining characteristic of resin prints is their ability to showcase incredible detail. Layer resolutions as fine as 25 microns allow for crisp edges, intricate textures, and lifelike forms. Miniature creators, jewelers, and medical professionals all rely on resin models because they capture nuances that would otherwise be lost in filament-based processes.

Another distinguishing factor is the wide material selection. Today’s resins are engineered for different purposes: castable varieties for jewelry and investment casting, flexible types for wearable designs, transparent resins for optical components, and biocompatible options for dental and medical use. This versatility makes resin printing adaptable across industries.

Advantages Over Traditional Methods

Resin 3D prints excel in producing prototypes and models that look nearly identical to final manufactured products. Their accuracy reduces the need for extensive post-processing, saving time during the design cycle. In comparison with filament-based methods, resin prints require less sanding or surface treatment, allowing creators to move from prototype to testing or casting more efficiently.

Additionally, the dimensional accuracy of resin parts is particularly useful in fields like dentistry and engineering, where even small deviations can affect usability. For artistic projects, the smooth surface finish enhances aesthetic appeal, making resin the preferred choice for display models and collectibles.

Post-Processing and Care for Resin Prints

Despite their precision, resin prints are not ready for use immediately after leaving the printer. Post-processing plays a crucial role in achieving their final quality. Prints are typically rinsed in isopropyl alcohol or specialized cleaning solutions to remove uncured resin. Afterward, they must undergo a curing stage under UV light to reach full strength and durability.

Proper handling is essential since liquid resin can be messy and requires safety precautions. Over time, cured resin parts may also be sensitive to prolonged sunlight exposure, so protective coatings or storage away from UV sources can help extend their lifespan.

Applications of Resin 3D Prints

Resin-based models are valued across diverse industries because of their balance of accuracy and adaptability. In healthcare, dental clinics produce crowns, aligner models, and surgical guides with reliable precision. Jewelers create intricate prototypes that can be directly cast into metals, allowing for innovative designs that were once impractical.

In the world of hobbies and gaming, enthusiasts use resin printers to produce custom miniatures, figurines, and cosplay accessories with remarkable detail. Engineers and product designers benefit from resin prototypes that mirror final products in both form and function, supporting quicker iterations during product development. Even in education, resin prints are used as teaching tools to illustrate anatomical structures or complex geometrical shapes.

Comparing Resin Prints with Filament Models

When evaluating resin versus filament, each approach has strengths, but resin stands out for quality. Filament models, while generally larger and more cost-effective, often show visible layers and require more finishing. Resin 3D prints, by contrast, emerge with refined surfaces and detailed features straight from the machine.

Cost and maintenance remain important considerations. Resin materials and post-processing equipment add to the expense compared to filament. However, for creators who prioritize professional-grade appearance and accuracy, resin offers unmatched results.

The Future of Resin Printing

As demand for high-quality 3D models grows, innovations in resin technology are making the process more accessible. New resin formulations are emerging with improved durability, flexibility, and eco-friendly compositions. Advances in monochrome LCD screens and light engines have accelerated printing speeds while reducing wear on hardware.

Manufacturers are also focusing on user convenience, introducing automated resin feeding systems, built-in air filtration, and smart connectivity features. These improvements are pushing resin 3D prints beyond specialized niches into broader adoption across industries and households.

Conclusion

Resin 3D prints embody the precision, versatility, and innovation that define the future of additive manufacturing. Their ability to capture fine details, deliver smooth finishes, and adapt to specialized applications makes them indispensable in fields ranging from healthcare to creative design. While they require careful handling and post-processing, the results consistently justify the investment.