The world of 3D printing has witnessed remarkable advancements over the past decade, introducing technologies that allow creators to produce intricate designs with exceptional accuracy. Among these innovations, resin 3d printers have become increasingly popular, providing a level of detail and surface smoothness that traditional FDM printers often cannot match. Whether for hobbyist projects, professional prototyping, or industrial applications, resin printing offers versatility and precision that caters to a wide spectrum of users. This article explores everything you need to know about resin 3D printers, including their technology, advantages, applications, and key considerations when choosing the right model.

What Are Resin 3D Printers?

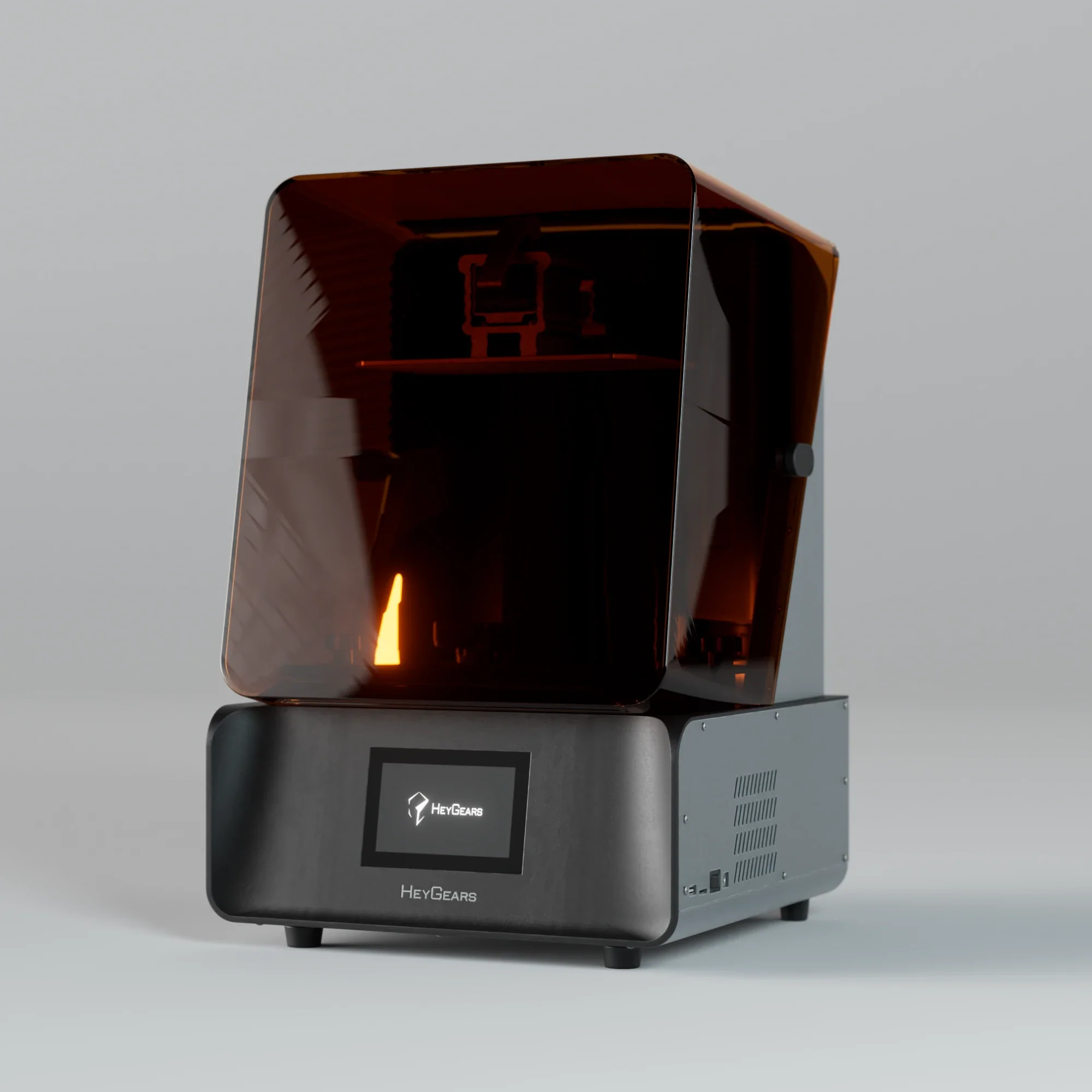

Resin 3D printers, also known as SLA (Stereolithography) or DLP (Digital Light Processing) printers, utilize liquid photopolymer resin as the printing material. Unlike filament-based 3D printers, which extrude molten plastic, resin printers cure liquid resin layer by layer using ultraviolet (UV) light. This process results in highly detailed models with smooth surfaces and sharp edges. Modern MSLA (Masked Stereolithography) printers combine the precision of SLA with the speed of DLP by using an LCD mask to selectively cure layers, offering a perfect balance between accuracy, speed, and affordability.

The precision of resin 3D printers makes them ideal for projects that require intricate detailing, such as miniatures, jewelry molds, dental applications, and small-scale engineering prototypes. The combination of high-resolution printing and smooth finishes often reduces post-processing work, saving both time and effort.

Advantages of Resin 3D Printers

One of the primary benefits of resin 3D printers is the remarkable print quality they deliver. Layer resolutions typically range from 25 to 50 microns, which allows for detailed textures, complex geometries, and a professional finish that FDM printers struggle to achieve. This precision is particularly valuable for creators working on miniatures, figurines, dental molds, or intricate prototypes.

Resin printers also offer flexibility through the variety of resins available. Users can choose from tough, flexible, transparent, or castable resins depending on the specific requirements of their projects. Modern resin 3D printers come with user-friendly features such as touchscreen interfaces, automated bed leveling, and pre-calibrated settings, making them accessible even to beginners. In addition, resin printing can often be faster than FDM printing for small, detailed parts, enhancing productivity without compromising quality.

Key Features to Consider When Buying Resin 3D Printers

Choosing the right resin 3D printer involves evaluating multiple factors to ensure it fits your specific needs. Print resolution is critical; higher resolution printers produce smoother surfaces and more precise details. Build volume is another important consideration. While smaller printers are suitable for compact desktop models, larger build areas allow for bigger or multiple objects to be printed simultaneously.

Resin compatibility should also influence your choice. Some printers only work with proprietary resins, while others accept third-party materials, offering cost flexibility and a wider selection of specialty resins. Ease of use is essential, especially for beginners, with features like automatic calibration, intuitive interfaces, and simple resin handling streamlining the printing process. Safety precautions are equally important since liquid resin can be hazardous; adequate ventilation and protective gear are necessary when operating these machines.

Applications of Resin 3D Printers

Resin 3D printers are widely used in a variety of industries and creative pursuits. In dentistry, they are used to produce precise molds, surgical guides, and dental aligners. Jewelry designers leverage resin printing for intricate molds and detailed decorative items. Artists and hobbyists can create high-quality miniatures, figurines, and decorative models. Engineers and product designers use resin 3D printers for prototyping complex parts, functional models, and components requiring tight tolerances, helping reduce development time and costs.

The availability of specialty resins, such as heat-resistant, biocompatible, or flexible types, expands the possibilities of resin printing even further. This versatility makes resin printers a valuable tool for professionals and enthusiasts seeking detailed and precise models across a wide range of applications.

Maintenance Tips for Resin 3D Printers

Maintaining your resin 3D printer is essential for achieving consistent results and prolonging its lifespan. Regular cleaning of the resin vat prevents cured resin debris from affecting print quality, while replacing worn FEP films ensures smooth layer formation. Proper storage of resin in cool, dark conditions prevents premature curing. Routine calibration and firmware updates maintain precision, while safety precautions such as wearing gloves and ensuring proper ventilation protect users from harmful resin fumes. Following these best practices maximizes both the efficiency and reliability of your printer.

Conclusion: Why Resin 3D Printers Are Worth the Investment

Resin 3D printers offer unparalleled detail, precision, and versatility, making them a preferred choice for hobbyists, artists, engineers, and professionals alike. Their ability to produce smooth surfaces, intricate designs, and high-resolution prints sets them apart from traditional FDM printers. By understanding the technology, key features, and applications of resin printers, you can select a model that aligns perfectly with your needs. Investing in a high-quality resin 3D printer ensures professional results, enhanced creative possibilities, and efficient production for projects ranging from miniatures to industrial prototypes.