What Are the Advantages of a Customized Industrial Steam Boiler for Modern Industries?

In the world of industrial production, efficiency and reliability are two essential factors that directly impact profitability. Among the many systems that drive industrial processes, the customized industrial steam boiler has become a cornerstone of energy generation. Unlike standard boiler systems that are designed with a one-size-fits-all approach, customized boilers are tailored to the specific needs of a facility. This ensures not only maximum output but also reduced operational costs and improved safety. As industries continue to grow more complex, the demand for customized steam solutions is rising rapidly.

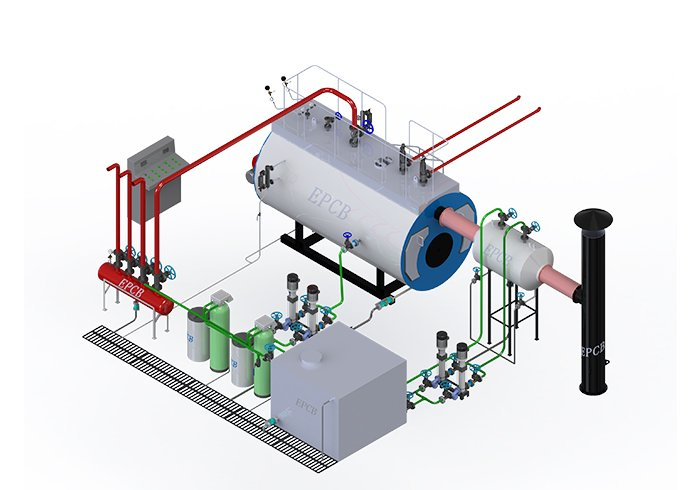

Understanding Customized Industrial Steam Boilers

A customized industrial steam boiler is a specialized unit designed to meet the unique requirements of a manufacturing plant or industrial facility. Steam boilers convert water into steam, which is then used to power machinery, sterilize equipment, or provide heating. Standard boilers may not always deliver the efficiency or capacity required for certain industries, which is why customization is essential.

Customization involves adapting the boiler’s design, size, pressure range, fuel type, and control systems to match the exact needs of a business. For example, a food processing plant may require a steady supply of clean, high-pressure steam for cooking and sterilization, while a textile factory may need a different type of boiler capable of handling continuous production loads. By designing boilers to fit these specific needs, manufacturers can ensure optimal performance and long-term reliability.

Key Benefits of a Customized Industrial Steam Boiler

The most important benefit of a customized steam boiler is enhanced energy efficiency. By tailoring the design to a facility’s requirements, less fuel is wasted, and the boiler operates at peak efficiency. This directly reduces energy bills, which is a significant advantage for industries with high fuel consumption.

Another major benefit is increased productivity. Customized boilers are engineered to deliver consistent steam output, ensuring that production processes run smoothly without unexpected interruptions. This reliability minimizes downtime, which is critical in industries where continuous operation is essential.

Safety is also a crucial factor. Since a customized boiler is designed specifically for a facility’s pressure and load requirements, the risk of system stress or failure is reduced. Advanced safety controls and monitoring systems can also be incorporated, ensuring that the boiler complies with industry standards and regulations.

How Customization Improves Industrial Operations

Customization in steam boilers is not limited to size and capacity. It often includes fuel options such as natural gas, oil, biomass, or coal, depending on what is most cost-effective and readily available for the business. Modern designs can also integrate automation and digital monitoring systems, which allow operators to control and track performance in real time.

Industries with unique space limitations also benefit from custom-built solutions. For example, a facility with limited floor space might require a compact vertical boiler, while larger plants might rely on horizontal boilers with higher capacity. Custom engineering ensures that the system fits seamlessly within the facility layout without compromising efficiency.

In addition, customized boilers can be built with special materials that resist corrosion and wear, especially in industries dealing with harsh chemicals or continuous heavy loads. This extends the lifespan of the system and reduces maintenance costs over time.

Applications of Customized Industrial Steam Boilers

The applications of customized industrial steam boilers span across multiple industries. In the pharmaceutical sector, these boilers provide sterilized steam essential for medicine production. Food and beverage manufacturers rely on them for cooking, pasteurization, and cleaning processes. In the textile industry, steam is used for dyeing and finishing fabrics. Power plants, chemical factories, and oil refineries also depend heavily on high-capacity customized boilers to sustain their operations.

Even within the same industry, steam requirements can vary significantly. This is why customization plays a vital role in aligning boiler performance with specific operational needs. By choosing a system designed for their exact processes, companies can optimize both production efficiency and cost-effectiveness.

Why Industries Prefer Customized Steam Boilers

Industries today face increasing challenges such as rising energy prices, stricter environmental regulations, and higher demands for product quality. Standard boilers may not always meet these evolving demands. Customized industrial steam boilers offer a solution by providing systems that are efficient, environmentally friendly, and tailored to long-term business goals.

For instance, many customized boilers are designed to meet emission standards, ensuring that businesses remain compliant with environmental laws. They also often integrate heat recovery systems, which recycle waste heat and further improve fuel efficiency. By addressing both regulatory and economic concerns, these boilers provide a future-ready solution for industrial facilities.

Oil/Gas Fired Steam Boiler

1. Key Selling Points:

Three-pass design for higher thermal efficiency and better fuel utilization.

Stable and high-quality steam output, ideal for food processing, textile, and manufacturing plants.

Customizable solutions in terms of capacity, pressure, and configuration to meet different industry needs.

Automatic control system, easy operation, and reduced labor cost.

High safety standards with multiple protection devices (low water, overpressure, flameout protection).

2. Typical Applications: Food factories, beverage plants, textile mills, manufacturing industries.

Oil/Gas Fired Thermal Oil Boiler

1. Key Selling Points:

High-temperature heating under low pressure, ensuring safer operation.

Precise temperature control, suitable for industrial processes requiring stable heating.

Closed-loop circulation system with high efficiency and lower energy consumption.

Flexible fuel options, including natural gas, light oil, and heavy oil.

Low maintenance and long service life with reliable operation.

2. Typical Applications:Paper mills, chemical plants, building materials, printing & dyeing industries.

Oil/Gas Fired Hot Water Boiler

1. Key Selling Points:

High efficiency and energy saving, with thermal efficiency above 90%, reducing operating costs.

Reliable performance for continuous and stable heat supply in industrial and civil heating systems.

Low-NOx combustion technology, meeting international environmental standards.

Compact structure and easy installation, suitable for new projects and system upgrades.

Durable design, made with high-quality materials for a longer service life and lower maintenance cost.

2. Typical Applications: Industrial heating systems, hospitals, schools, hotels, residential heating.